Effect of friction on axial clamping force of threaded fasteners

20

2024.8

Author

493

Read volume

In the fastening connection, the threaded connection can tightly fix the connected parts, and the main role is the axial clamping force converted into the torque applied to the bolt or nut. However, due to the influence of many factors such as structural functions, part surface accuracy, control accuracy, and friction properties of the connection pairs during the assembly process, about 90% of the torque is applied to overcome the friction force after the bolt is tightened, and only 10% of the torque is transformed into an axial clamping force.

Friction is mainly generated between the rotating part and the clamping part and in the thread. By reducing friction in threaded connections, the conversion rate of torque into axial pre-tightening force can be increased and the stability of threaded connections can be improved. However, when the friction force in the threaded connection is too small, the bolt easily slips and causes the connection to become loose. Therefore, we need to control the range of friction force during the threaded connection rather than just considering how to reduce friction.

Methods to control friction usually use several methods such as surface treatment of the parts and adding lubricant or lubricating oil to the joints. However, the method of adding lubricant or lubricating oil is generally not recommended because under the same installation torque, too small friction coefficient may cause tensile deformation or fracture failure (over-tightening) of the bolt. The more common surface treatments include electroplating, blackening, phosphating, dacromet, etc. The friction coefficients of different coatings are also different. From the perspective of the stability of the friction coefficient, phosphating is the most stable among all surface treatments. One, so the surface treatment of automobile hub bolts is generally phosphating. In addition, in order to ensure the fastening reliability of the connection during operation, it is also necessary to ensure that the surface of the parts is free of foreign matter such as iron filings, welding slag, and rust.

For the axial clamping force of threaded fasteners, we can also control the friction coefficient of the bolt to ensure the life of the fastening connection. The friction coefficient of a threaded fastener is affected by many factors such as its material, surface treatment, manufacturing process and thread accuracy. The relationship between the total friction coefficientμ and the tightening torqueTand the axial clamping forceFis shown in Formula (1):

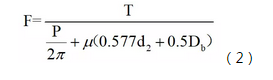

Where, P is the thread pitch, d2 is the thread middle diameter, and Db is the friction diameter of the lower supporting surface of the bolt head. The clamping force F can be expressed by Equation (2):

When the test bolt is selected, d2 and Db are fixed, and when the tightening torque T is constant, the larger the total friction coefficient, the smaller the axial clamping force F acting on the thread.

In theory, the relationship between the tightening torque T, the axial clamping force F of the bolt during the tightening process and the friction coefficient and thread shape and size is as follows:

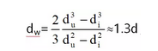

Where, ms is the friction coefficient of the thread pair;mw is the friction coefficient of the end face;dp is the effective diameter of the bolt, and dp of the coarse thread is 0.906d;dw is the equivalent diameter of the friction circle of the end face.

du and di are the outer diameter and inner diameter of the friction circle respectively;d is the nominal diameter of the thread;b is the thread rise angle, and a¢ is the half angle of the thread profile in the vertical section, which is about° 29.58¢. Items 1, 2, and 3 on the right side of formula (3) can be understood as the torque consumed by friction of the thread pair, the torque consumed by bolt elongation (producing axial clamping force), and the torque consumed by friction of the end face.

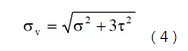

The bolt is subjected to a tension-torsion compound stress when tightening. According to the third strength theory, the allowable equivalent stress v of the boltσ can be obtained according to Equation (4).

Where, is the tensile stress generated by the axial clamping force F of the bolt,

τThe shear stress generated by the torque Ts suffered by the bolt shank,

According to Equation3, the torque on the bolt is applied:

Taketg=0.05( coarse thread) anddp=1.05ds and substitute them into equation (4) to obtain:

It can be seen from Equation (5) that the greater the friction coefficient of the thread pair, the greater the equivalent stress of the bolt under the same axial force. In other words, after the bolt strength is selected, the greater the friction coefficient, the smaller the axial force the bolt can withstand. The smaller the friction coefficient, the greater the axial force the bolt can withstand.

The friction coefficient is a comprehensive indicator to evaluate the manufacturing level of bolts. The friction coefficient determines the torque value and the axial clamping force. The dispersion of the friction coefficient affects the change of the axial clamping force that the bolt can provide during assembly. Especially when tightening bolts by torque, the greater the dispersion of the friction coefficient. In order to ensure the axial force of assembly, assembly tools with higher precision are usually used during field operations to more strictly control the range of assembly torque. This not only increases assembly costs, but also fails to achieve the expected stabilization of the axial force. The optimal axial force control must start from the range of stable friction coefficients.

Online Selection

1V1 Customer Service