Popular science of drawing technology

20

2024.8

Author

647

Read volume

Among industrial frame parts, the raw materials of some products cannot be hot processed to strengthen the internal organization, such as stainless steel or aluminum alloy. For such products, we usually use cold processing processes to improve the structure of the crystal structure, such as cold drawing, cold rolling, cold forging, cold stamping, etc., different processing processes have different degrees of strengthening the metal materials and different applications. For stainless steel bolts, a popular product of Wulian, they are mostly processed through drawing processes. It is convenient to modify the material size and enhance the performance of stainless steel bolts. The following Xiaowu introduces the processing methods, methods and advantages of the drawing process, and provides some reference for everyone in production and selection.

Drawing refers to a metal forming process in which external force acts on the front end of the metal to be drawn and passes it through a mold with a certain shape. Usually after drawing, due to plastic deformation of the material, its microstructure and mechanical properties are obtained to a certain extent. Improvement and strengthening, especially the yield strength of steel can be increased by 20% to 30%, which has the effects of rust removal and straightening. Drawing is usually carried out at room temperature, but for some metals with high strength and poor plasticity, warm drawing or hot drawing methods can be used during processing to ensure the quality of the formed workpiece.

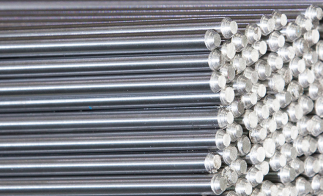

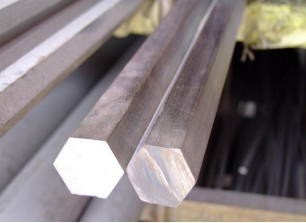

Drawing can be divided into solid material drawing and hollow material drawing according to the type of product. Solid material drawing is generally bar, profile and wire, and hollow material drawing can be divided into special-shaped hollow material and pipe. For pipes, drawing can be divided into various methods such as empty drawing, long core rod drawing, fixed core head drawing, floating core head drawing, pipe jacking and expanding diameter drawing.

The advantages of drawing are:

1.& nbsp; Can realize automated processing, mass production, and high production efficiency;

2.& nbsp; Tools and equipment for drawing production are simple to operate and easy to maintain;

3.& nbsp; Can improve the strength and hardness of the material;

4.& nbsp; The drawn products have accurate size and good appearance smoothness;

5.& nbsp; Suitable for the production of filaments and tubes of various metals and alloys.

The disadvantage of drawing is that the surface of the drawn material is prone to surface scratches, wrinkles, bends, eccentricity, cracks, etc., among which eccentricity and wrinkles are the most common. Therefore, during the production process, it is necessary to ensure that the operation during the metal drawing process is accurate and avoid these phenomena.

Online Selection

1V1 Customer Service