nondestructive testing

20

2024.8

Author

393

Read volume

Non-destructive testing (NDT) is a method that uses light, dots, magnetism and sound to detect whether there are defects or inhomogeneities on the surface or inside of the inspected object without damaging the sample or causing any impact on the sample. It mainly collects and sends data such as the size, location, nature and number of defects of the sample, and then understands the status of the inspected object, the remaining service life and other information.

There are five common non-destructive testing methods: radiographic testing (RT), ultrasonic testing (UT), magnetic particle testing (MT), liquid penetrant testing (PT) and eddy current testing (ET).

RT refers to using X-rays or G-rays to penetrate the sample to make the film sensitive, and then confirming the internal defects of the sample through the information displayed on the processed film.

Advantages: Intuitive images can be obtained and qualitatively accurate; test results can be stored for a long time; suitable for volumetric defects.

Disadvantages: It is more suitable for thinner materials. When testing thicker materials, higher energy is required, and the inspection sensitivity will also decrease; the inspection cost is high and the speed is slow.

UT studies the reflected, transmitted and scattered waves on the surface or inside of the sample to obtain macro defect detection reports, geometric property measurement results, changes in organizational structure and mechanical properties of the sample.

Advantages: Strong penetration ability, which can detect steel forging samples several meters long; high inspection sensitivity; low inspection cost and fast speed; suitable for area defects.

Disadvantages: It will be affected by the material and grain size; the test results are not intuitive; it is difficult to detect samples with irregular shapes.

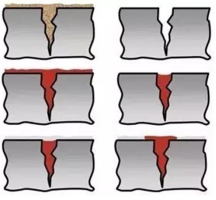

The principle of MT is that discontinuities on the surface of ferromagnetic materials will cause changes in the magnetic field lines and generate leakage magnetic fields. After absorbing magnetic powder, magnetic traces will be formed, thus showing the location and shape of the discontinuity.

Advantages: It can detect unprocessed, semi-processed and processed samples; it can detect defects such as cracks, inclusions, hair lines, white spots, folds, cold stops and looseness.

Disadvantages: It cannot be used on the surface of austenitic stainless steel and welds welded with it as a welding rod, nor can it be used on other non-magnetic materials; it cannot be detected for deep defects.

PT uses a penetrating agent containing fluorescent dyes to penetrate into cracks and defects on the sample surface through capillary action, and then uses an imaging agent to display the position of the penetrating agent, thereby detecting the morphology and distribution of defects on the sample surface.

Advantages: Small restrictions by materials and processing methods; high detection sensitivity; intuitive display, convenient detection, simple operation, low cost, and fast speed.

Disadvantages: It is impossible to detect loose, porous and rough surfaces of materials; it is impossible to detect internal defects of samples, which requires high operating requirements for testing personnel.

ET: It is mainly used for the detection of surface and near-surface defects of conductive metals. A coil with alternating current is placed on the sample and the distribution and size of eddy currents are detected to determine whether there are defects.

Advantages: The coil does not need to directly contact the sample during testing; the testing speed is fast; automation can be achieved.

Disadvantages: High requirements on sample material; only defects on the surface or near surface of the sample can be detected; not suitable for samples with complex shapes.

Judging from the content of appeal testing, testing a fastener usually requires matching the inside and outside or determining which non-destructive testing item to select based on the material.

When testing bolts, according to some properties of the bolts, we usually choose UT, MT, and ET.

(Tuyuan Network)

Technical support: Guo Honghua

Editor: Liu Kangli

Online Selection

1V1 Customer Service