metal working process

20

2024.8

Author

449

Read volume

In industrial production, in order to meet various production needs, metal processing processes and methods are also diverse. At present, metal processing processes can be divided into two categories: cold working forming and hot working forming. Among them, common processing methods can be divided into cutting, drawing, rolling, stamping, forging, casting and other forms.

Cutting is the most commonly used process in cold metal processing. It is divided into various processing methods such as turning, drilling, milling, grinding, boring, and planing. Therefore, it can be used to process metal parts of various shapes., the application range is wide, and automatic processing can be realized to improve production accuracy. During the processing process, the cutting process will not change the internal structure of the metal itself and avoid changes in mechanical properties.

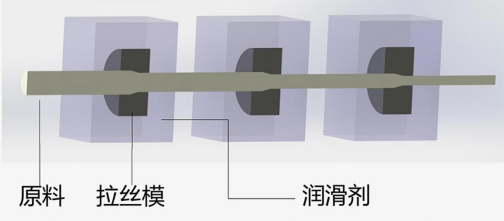

Drawing is also a type of cold working, so it can also be called“ cold drawing” or“ cold drawing”. During processing, external force is used to pull the front end of the metal, and the plasticity and toughness of the metal itself are used to plastically deform it, thereby achieving the purpose of production. Drawing is usually suitable for the processing of metal parts such as pipes, wires, and bars, and can achieve a workpiece with a uniform cross-section at high productivity.

Rolling and stamping can be divided into hot rolling and cold rolling, hot stamping and cold stamping according to the temperature during processing.

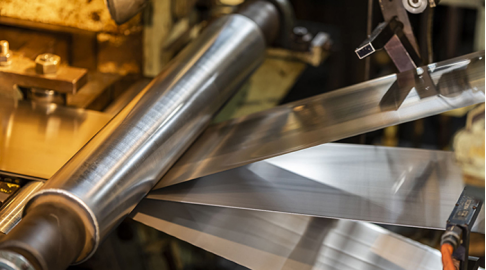

Rolling is a process in which metal is passed between two rotating rolls to obtain materials such as sheet metal. In the industrial production process, hot rolling is used much more frequently than cold rolling, because when hot rolling is heated, the metal undergoes plastically deformation above the recrystallization temperature, resulting in complete recrystallization, improving the internal organization of the metal, and the processing of the metal. The performance of the metal has also been improved, which is conducive to subsequent reprocessing; while cold rolling will cause the metal to undergo cold work hardening, reducing the toughness of the metal, which is not conducive to reprocessing.

Stamping is the use of presses and molds to exert force on metal materials to plastically deform or plastically separate the metal to obtain the metal of the required shape and size. The common blank for stamping is rolled plate, which is divided into two treatment methods: cold stamping and hot stamping according to the performance of the plate. Hot stamping is for plates with high deformation resistance and poor plasticity; cold stamping is often used for thin plates at room temperature.

Forging applies force to the metal through forging machinery, causing the metal to plastically deform, thereby obtaining appropriate size and shape, and obtaining certain mechanical properties. Forging objects are different from casting objects. Forging is to process blanks with a certain size and shape; casting objects are blanks or even waste materials.

Casting is a hot working process in which liquid metal is poured into a mold and cooled and formed. Casting can realize the processing of complex shaped parts, especially parts with complex inner shapes; casting is a very economical forming process, and raw materials can use surplus materials or even waste materials; at the same time, casting is also the only way to shape materials with poor plasticity such as cast iron. However, the labor environment for casting is poor, and the scrap rate of formed parts is relatively high.

Online Selection

1V1 Customer Service